Accurate Data Acquisition Across the Entire Train

Modern trains are complex high-tech systems: high-performance traction drives, sophisticated bogies, tightly integrated control and power systems, and passenger comfort modules packed into limited space. Testing them requires data from hundreds of sensors—installed across multiple cars, from the bogie to the roof.

Centralized DAQ architectures quickly hit their limits: long analog cables degrade signals, EMI distorts data, and installation takes time and effort.

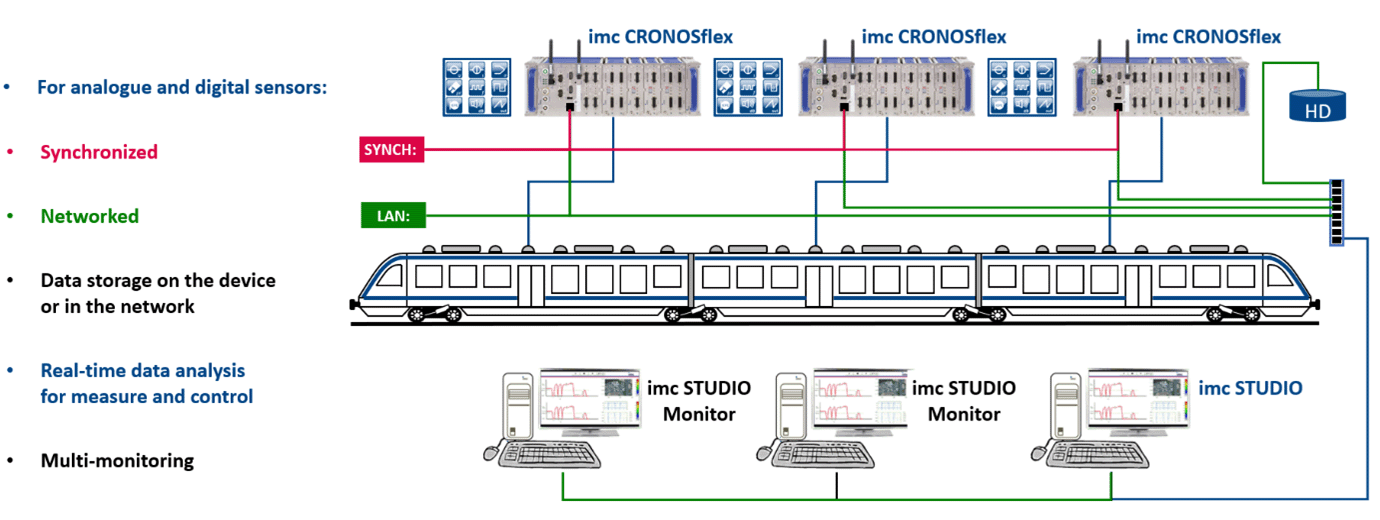

imc distributed data aquisitions systems capture signals right where they originate—synchronously across all measurement points, with robust hardware and high signal integrity. The result: a precise, system-wide view of the vehicle, without the burden of long analog wiring or susceptibility to interference.

Typical applications

- Full-train test runs and validation

- Functional testing of bogies, brakes, or HVAC systems

- Structural and fatigue measurements on car bodies

- Comfort and vibration testing (EN 14363, ISO 3381, ISO 3095)

- Thermal and climate testing

Ces méta-informations sont précisément associées aux canaux de mesure correspondants, stockées et combinées aux canaux vidéo pour former un système intégré de canaux analogiques, numériques, virtuels (calculés), de bus de terrain et multimédias. Ce "pool" complet d'informations de mesure est ensuite disponible pour une gestion avancée du stockage, une gestion de base de données et une analyse plus poussée à l'aide d'imc FAMOS ou d'autres outils tiers. Grâce à cette configuration, les experts peuvent obtenir des résultats précis, basés sur des données, pour le développement et les essais de divers composants tels que les freins, la suspension ou les systèmes de propulsion.

Why Distributed Architectures Work Better

When signal paths are long or space is tight, traditional centralized systems struggle. A distributed setup delivers clear advantages:

Shorter Signal Paths – Higher Signal Quality

Signals are digitized just a few meters (feet) from the sensor instead of tens of meters (dozens of feet) away. The payoff: minimal attenuation, less noise, and far greater EMC immunity.

Up to 70 % Less Cabling

Fewer cables mean fewer failure points. Digital transmission is immune to attenuation and interference, and faulty modules can be isolated and replaced quickly.

Higher Reliability

Fewer cables mean fewer failure points. Digital transmission is immune to attenuation and interference, and faulty modules can be isolated and replaced quickly.

Maximum Flexibility

Modules can be repositioned, added, or swapped without re-wiring the whole setup—ideal for prototype programs where test configurations change frequently.

Key Requirements for Distributed Systems:

Distributed doesn’t automatically mean synchronized or robust. Engineers should check for:

- Microsecond-level synchronization

network timestamps alone aren’t precise enough - Flexible power concepts

Power-over-Ethernet (PoE) or local feed-in options reduce cabling - EMC-robust data transmission

Rail environments exposes systems to strong electromagnetic fields - Centralized control

users shouldn’t have to manage complexity module by module.

Not every distributed system meets these requirements—so it’s worth asking the right questions.

How imc Solves These Challenges:

With more than 30 years of field experience and hundreds of successful rail projects worldwide, imc Test & Measurement offers proven DAQ platforms for distributed rail testing—from prototype evaluation to certification.

Precise Synchronization Down to the Microsecond

Distributed imc CRONOSflex and imc ARGUSfit systems are networked via high-speed, real-time buses:

imc CRONOSflex: based on EtherCAT, a deterministic fieldbus for high-precision synchronization and fast data exchange over large channel counts.

imc ARGUSfit: uses fiber-optic links—immune to interference and suitable for long distances.

All imc DAQ systems support multiple synchronization methods:

- Cable sync for compact setups

- GPS or IRIG-B for long-range applications

- PTP (Precision Time Protocol) over Ethernet for distributed networks

A proprietary imc process guarantees sample-accurate timing across more than 1,000 channels distributed over multiple cars.

Power and Data over a Single Cable

CRONOSflex modules support Power-over-Ethernet, carrying power, data, and sync on one line. For larger networks, separate power modules can be integrated wherever needed—keeping installation clean and scalable.

Built for the Rail Environment

imc systems are designed for real-world rail conditions: shock- and vibration-proof, with optional extended temperature range from –40 °C to +85 °C (–40 °F to +185 °F ) and high EMC immunity. The imc PROTECT series is built for the toughest test environments.

Modular Architecture for Every Task

With imc CRONOSflex and imc ARGUSfit, imc offers two fully modular and distributed DAQ systems that can be flexibly combined to cover any rail testing requirement. Both platforms follow the same principle: measurement modules are positioned close to the sensors, digitizing signals right at the source and transmitting them synchronously across the train:

- imc CRONOSflex: A high-precision, modular DAQ system for large channel counts and demanding test programs. Ideal for certification, validation, and multi-car measurements, it supports EtherCAT networking, Power-over-Ethernet, and long-distance scalability.

- imc ARGUSfit: An ultra-compact, click-modular DAQ system designed for confined installation spaces such as underframes or interiors. Its fiber-optic link ensures interference-free operation and high data rates over extended distances.

For specialized measurement tasks, these systems can be seamlessly expanded with complementary imc solutions:

- imc BUSDAQ: A fieldbus data logger (CAN, MVB, Ethernet, etc.) that synchronizes perfectly with all imc DAQ platforms.

- imc Telemetry: For wireless signal acquisition from rotating components such as wheelsets or brake discs, transmitting measurement data reliably to the imc DAQ system

Together, these modular systems provide engineers with a flexible, distributed measurement architecture—scalable from individual subsystems to complete trains.

Important:

All imc systems share a common time base and can be synchronized sample-accurately—enabling perfectly aligned data across all modules, even when distributed over multiple cars.

Centralized Control and Real-Time Insight

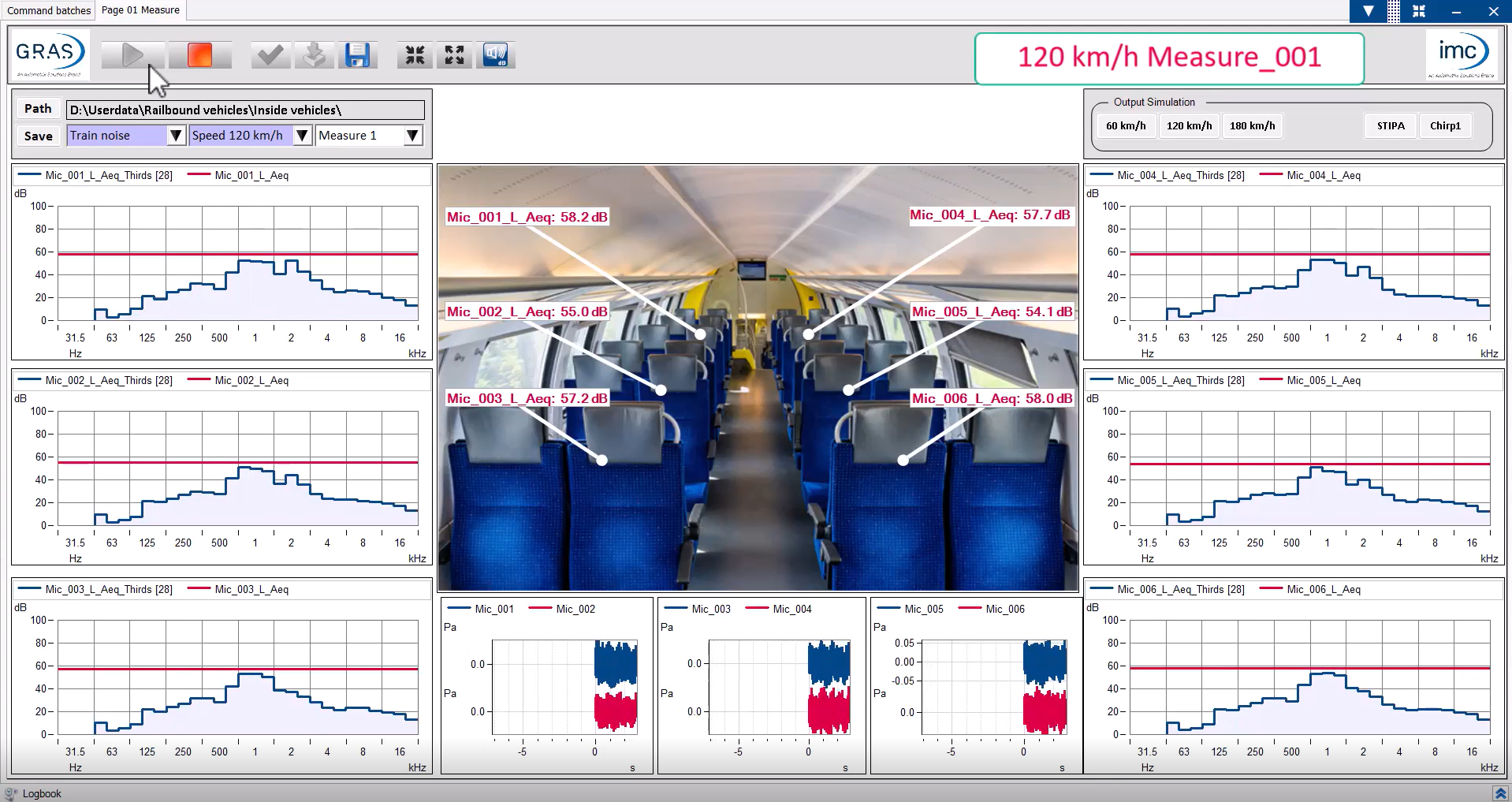

With imc STUDIO software, all distributed modules can be configured, controlled, and monitored from one interface—no matter where they sit in the train.

Engineers can:

- Visualize and monitor signals live

- Automate measurements and trigger on events

- Run first analyses during test runs

- Detect limit violations instantly

Seamless integration with imc FAMOS allows detailed post-processing, automated evaluation, and customized reporting.

From measurement to report—a continuous, efficient workflow for rail testing.

Fits Right into Your Development Workflow

imc DAQ systems integrate easily into existing toolchains:

- Import of sensor lists, thresholds, and metadata

- Export to MATLAB®, Python®, or DIAdem™

- Standard formats (MDF4, CSV, HDF5) for universal data access

- Direct links to databases and network storage

Proven in the Field

From Prototype to Series Approval

During train development, hundreds of sensors record strain, temperature, and acceleration across the vehicle.

Distributed imc CRONOSflex modules digitize these signals at the source and stream them synchronously to the base unit—providing real-time insight into entire subsystems.

High-Speed Train Certification

For the certification of the Frecciarossa 1000, Italcertifer captured more than 300 channels across several cars using imc CRONOSflex and CRONOScompact.

Acceleration, force, temperature, and bus data were logged synchronously at up to 100 kS/s per channel and analyzed in real time.

Conclusion: Efficient, Rugged, Connected

imc distributed DAQ systems provide a solid foundation for safe, efficient, and standards-compliant testing of modern rail vehicles. From individual components to entire trainsets, the modular concept offers maximum flexibility with minimal installation effort.

Your Benefits:

- Up to 70 % less cabling

- Best-in-class signal quality through at-source digitization

- Microsecond-accurate sync across 1,000 + channels

Field-proven in hundreds of rail projects worldwide.