Une flexibilité maximale pour vos mesures

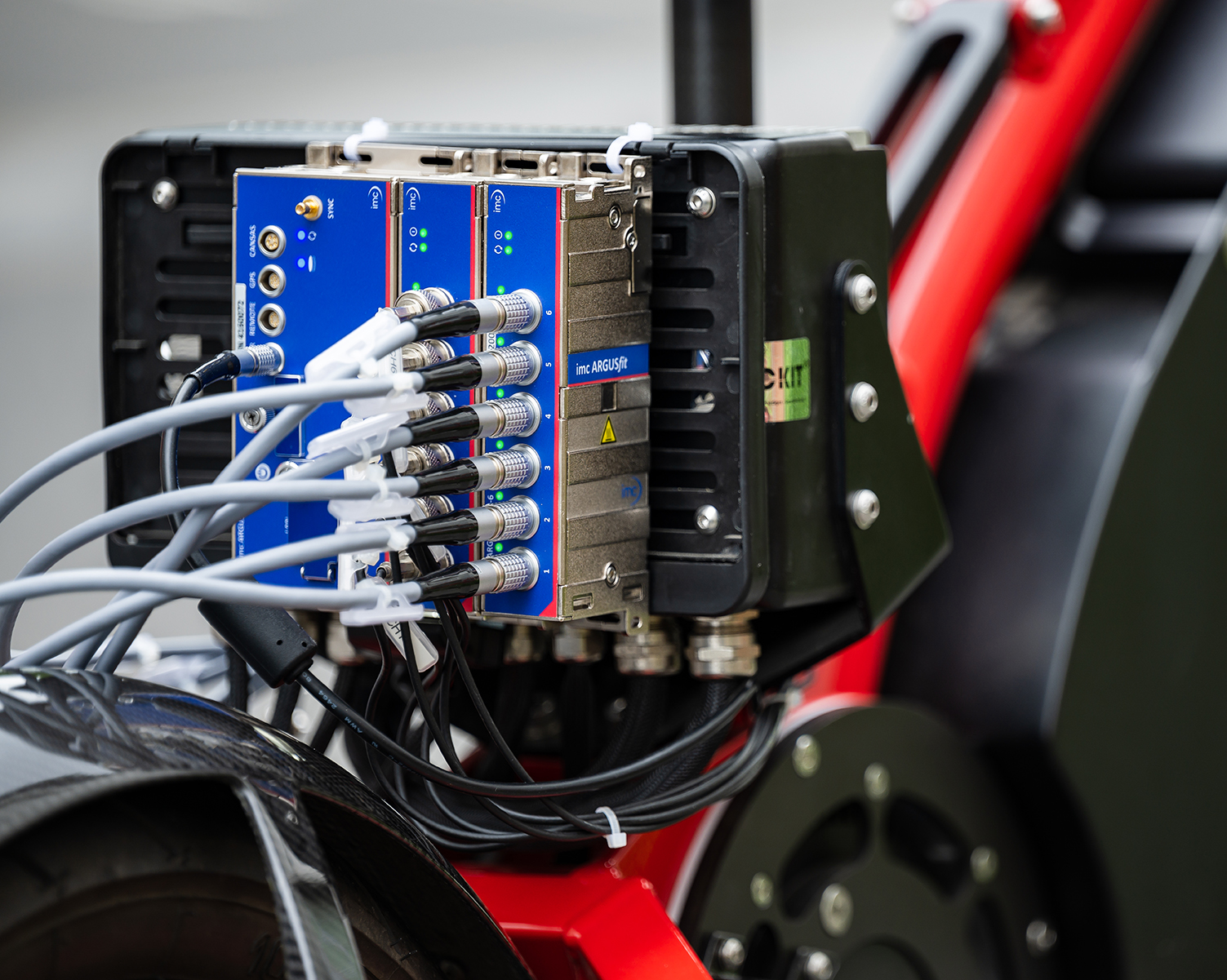

Découvrez imc ARGUSfit - le système de mesure puissant et flexible dont vous pouvez facilement assembler les modules par un mécanisme d'encliquetage. Avec sa haute densité de canaux, sa conception compacte et son fonctionnement autonome, il permet des mesures précises dans de nombreuses applications, du test de prototypes à la maintenance de machines et d'équipements.

NEW:

imc ARGUSfit-BASE W-LAN

ARGUSfit base unit with WIFI connectivity

NEW:

ENC-6 for ARGUSfit

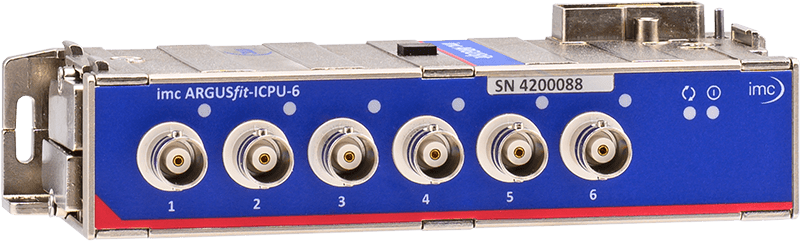

6-channel measurement amplifier for pulse signals & incremental encoder sensors

NEW:

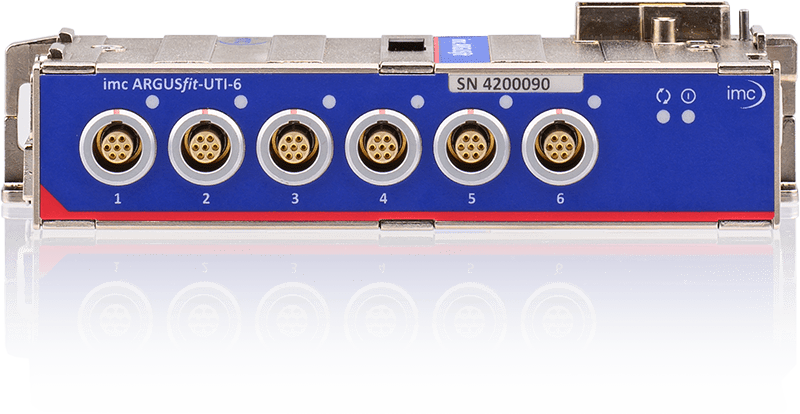

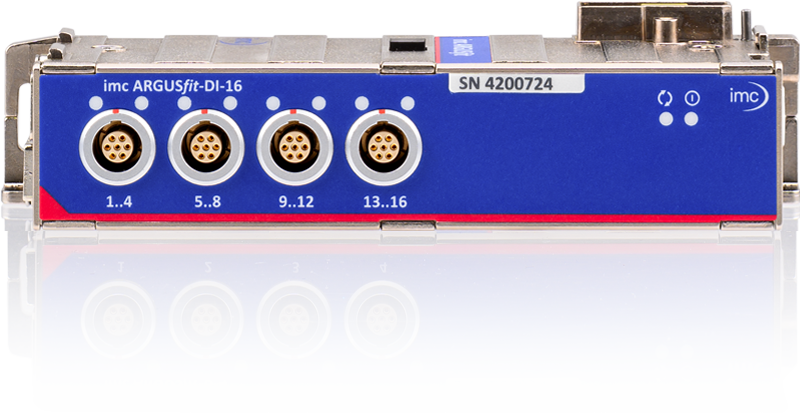

DI-16 for ARGUSfit

16-channel digital input module

NEW:

T-10 for imc ARGUSfit

10-channel amplifier for temperature measurement with thermocouples

UPS-NiMH for imc ARGUSfit

Battery buffered UPS for imc ARGUSfit (ARGFT) and imc CANSASfit (CANFT)

Module overview

imc ARGUSfit - Points forts

La conception modulaire du système de mesure, avec ses modules comprenant des conditionneurs de précision et des interfaces de communication, vous offre la flexibilité dont vous avez besoin pour vos tâches quotidiennes. Enregistrez de manière synchrone une grande variété de signaux : signaux analogiques et numériques, données de bus industriel, données audio à une fréquence d'échantillonnage totale de 5 MS/s et traitez-les directement en temps réel.

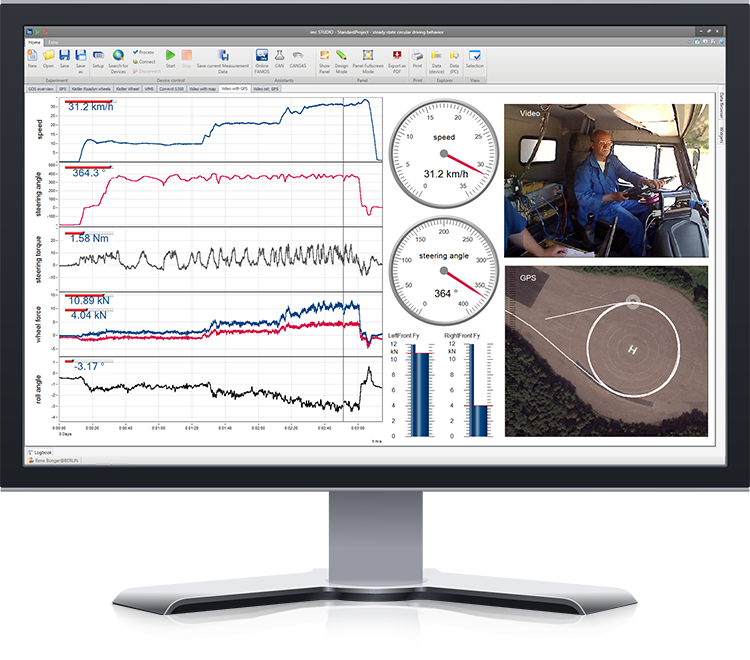

Software: Convivialité et facilité d'utilisation

Grâce au logiciel de mesure intuitif et complet imc STUDIO, imc ARGUSfit peut être configuré de manière particulièrement conviviale et même les mesures complexes sont faciles à réaliser. Avec imc STUDIO, vous avez un contrôle total sur l'ensemble de votre processus de mesure : Que vous souhaitiez configurer votre imc ARGUSfit pour des tests mobiles rapides en mode "boîte noire", mettre en place une surveillance en direct pour des centaines de canaux - imc STUDIO combine tous les outils importants de l'acquisition de données, de la visualisation, de l'analyse et de l'automatisation dans un seul logiciel.

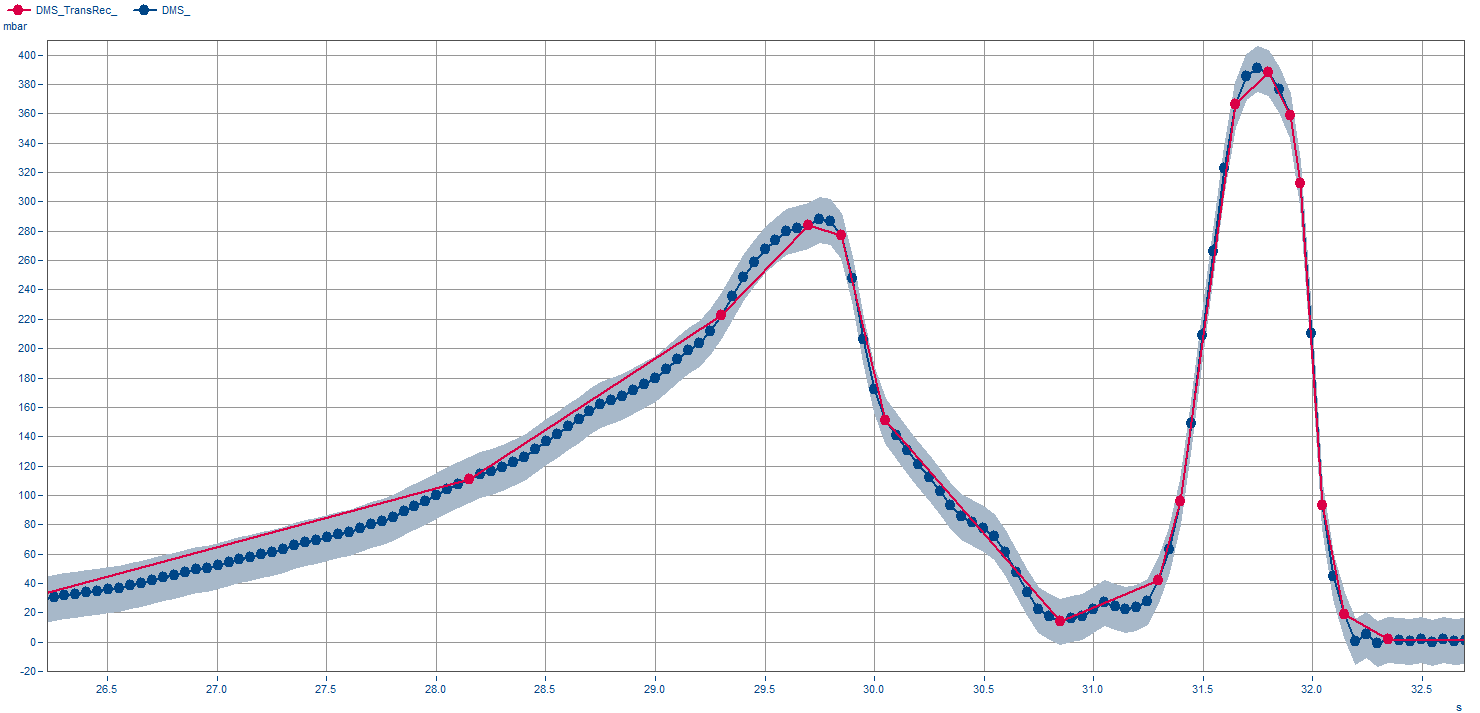

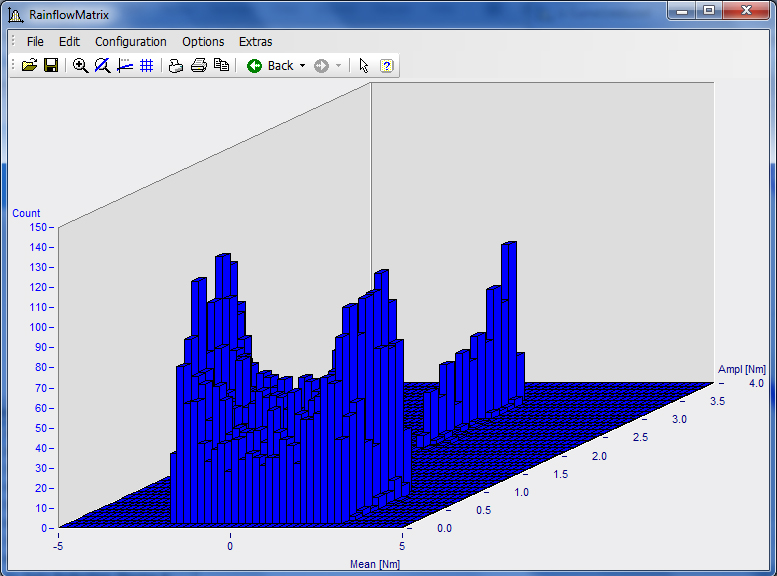

Real-time Analysis within the Device

Get results while the measurement is still running. With the integrated imc Online FAMOS signal analysis platform, you can calculate and analyze your measurement data in real-time. Use a convenient wizard to create your personal real-time analyzer: simply drag and drop from a comprehensive collection of mathematical and statistics functions as well as ready-made analyses such as FFT, classification and order tracking. This makes it possible to create your own evaluation algorithms and set up smart data analysis without any programming at all.

This means that reduced, refined and intuitive results are available during the live running measurement - bevor it has even completed. Thus, during a test drive for example, you get direct feedback on the test in progress, allowing the user to immediately respond to it, like adapting driving maneuvers accordingly.

Versatile Solutions Across All Industries

Automotive

Precise data for development, validation,

and performance testing

Commercial Vehicles

Reliable measurements for durability

and efficiency on the road

Railway

Robust data acquisition for safety,

comfort, and system monitoring

Heavy Duty Machinery

Rugged solutions for testing and

monitoring under extreme loads

Aerospace

High-precision results in demanding

environments, from lab to flight

Defense

Trusted measurements for mission-critical

systems in the toughest conditions

Typical Applications

Monitoring Machines and Equipment

To ensure the smooth operation of expensive or safety-critical machinery and equipment such as wind turbines, turbines, valves, etc., continuous monitoring is crucial. This task places high demands on measurement technology, especially with regard to reliable and failure-proof operation. ARGUSfit provides you with a solution that is based on a robust real-time operating system and has been specially developed for stand-alone 24/7 operation.

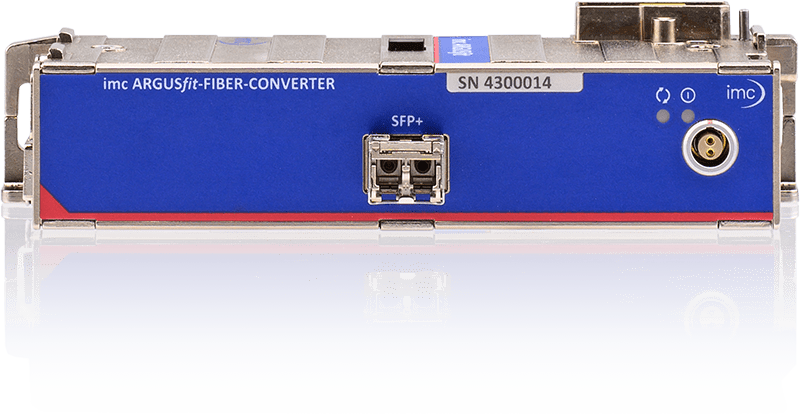

Thanks to the imc Online FAMOS real-time platform, ARGUSfit offers the possibility of performing real-time analysis and monitoring critical values autonomously. This enables early detection of any abnormalities and a proactive response to potential problems. In addition, there is the option to distribute the components and amplifiers of the ARGUSfit system via optical fiber connections, immune to any electromagnetic interference. This allows measurements to be made with just one single system even in extensive facilities or across multiple sites.

Prototype Testing

Whether car, motorcycle, construction machine or electric bike - in prototype testing, it is often a great challenge to place and install a DAQ system. With the particularly compact housing and high channel density of the imc ARGUSfit systems, this task is now easier than ever before. Even for 100 temperature channels, no more space is required than for a usual shoe box. The stand-alone operating system allows data to be stored directly on an SD card, so no additional PC is required. In addition, thanks to the GPS connectivity, position data, distances, and speeds can be recorded in real-time.

A clickable UPS module protects your measurements and data from unexpected power failures, buffering up to 30 seconds or with outages beyond that time, shutting down in an orderly fashion.

Another advantage of imc ARGUSfit is the availability of a clickable CAN-FD fieldbus module. This allows you not only to record data from analog sensors but also from the vehicle bus. This comprehensive recording and analysis of vehicle data is required to provide deeper insights into the behavior of a prototype. The modular expandability with further such interface modules makes the imc ARGUS system particularly flexible for responding to growing test requirements with very many buses. The spatial distribution of these CAN interfaces via fiber optics also allows installation close to the signal sources to avoid potential EMI interference or limitations of Baud rate. In this way, ARGUSfit helps users in vehicle testing to identify potential for improvement more quickly and to gain valuable insights that drive further development of the product.

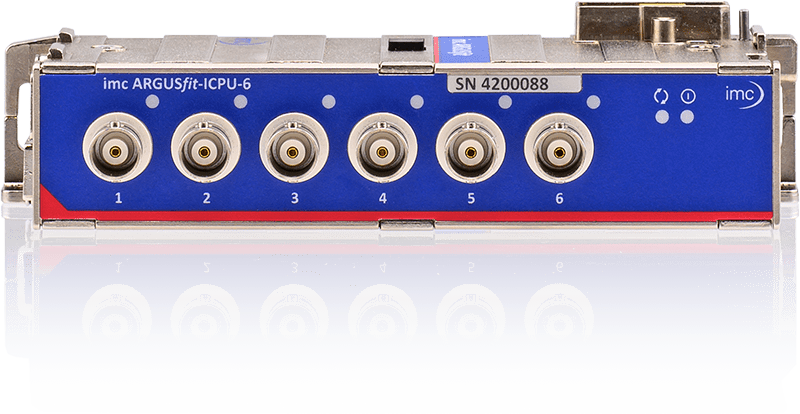

Vibrations & Shock Measurements

Vibrations and shocks are often undesirable in vehicles, machines, and infrastructures, as they stress structures and materials, lead to premature wear, and can potentially cause serious damage. To minimize these issues during product development or monitor them during operation, precise vibration measurements are essential. They enable the determination of resonant frequencies, the evaluation of material stress, and an estimation of service life.

The low-noise ICP data acquisition module from imc ARGUSfit, which offers a sampling rate of up to 500 kHz per channel, provides you with the ideal equipment for multi-channel vibration measurements. Even over long distances of hundreds of meters, you can use the system in a distributed manner to perform comprehensive measurements. Extensive NVH analysis functions provide additional support and facilitate the evaluation of the test results.

With imc ARGUSfit, you have a powerful tool at hand to effectively record and analyze shocks and vibrations. This enables you to identify potential problems at an early stage, take appropriate measures, and improve the reliability and service life of your products and systems.

Clever Click Connection

Engineers and technicians value modular systems that enable them to perfectly adapt their data acquisition system to their changing tasks at any time. But a common source of frustration and potential errors is any extra cable connections between modules. At imc, we listen to our customers and turn their wishes into innovations, by developing the imc clicking system for module connections. What makes it special is that it connects the modules not only mechanically, but also electrically and data-wise, completely without tools. Goodbye, unnecessary cables - welcome, click connection!

Un système idéal pour tous les types de mesures

Le système modulaire imc ARGUSfit révolutionne le quotidien des ingénieurs de mesure et d'essai en leur offrant une flexibilité inégalée. Imaginez pouvoir ajuster votre système à tout moment, sans fil et sans outils, simplement en connectant les modules entre eux. Les modules ARGUSfit, capables de capturer des données jusqu'à 500 KHz par canal, sont parfaits pour l'acquisition de données vibratoires, sonores, tension, courant et tous type de capteurs. Pour les signaux de mesure plus lents comme les températures, les pressions et les forces, les modules CANSASfit se connectent facilement à l'unité de base.

Mais ce n'est pas tout. ARGUSfit peut être utilisé de manière distribuée pour une flexibilité encore plus grande. Les modules de mesure et de bus industriels peuvent être connectés à l'unité de base sur des centaines de mètres grâce à des connexions en fibre optique. De plus, les modules CANSASfit peuvent être alimentés en mode distribué via l'interface imc CANSAS ARGUSfit et connectés avec des câbles CAN.

Avec imc ARGUSfit, libérez votre potentiel et repoussez les limites de vos projets d'essais !

Le boîtier ultra-compact et robuste ARGUSfit permet d'effectuer des mesures sur des machines et des systèmes dont l'espace est limité et offre de nombreuses voies dans un espace très restreint. En combinaison avec sa capacité d'autonomie, le système est idéal pour les tâches de surveillance 24/7 ou l'acquisition mobile des données dans les véhicules et les machines.

![[Translate to French:] imc ARGUSfit B-4 [Translate to French:] imc ARGUSfit B-4](/fileadmin/Public/Products/Measurement_Hardware/imc_ARGUSfit/ARGFT-B-4_001_wetfloor_LR.png)