Why Measure Wheel Forces?

Wheel force measurement in rail vehicles captures the loads at the wheel–rail interface – the very basis of safe and efficient railway operations. Reliable wheel force data is essential for vehicle dynamics analysis, condition monitoring, and regulatory approval of new vehicles (e.g., according to EN 14363). Direct measurement delivers dependable input variables to optimize design, maintenance, and operation – from reducing track wear and component fatigue to improving operational safety and vehicle availability.

How Are Wheel Forces Measured?

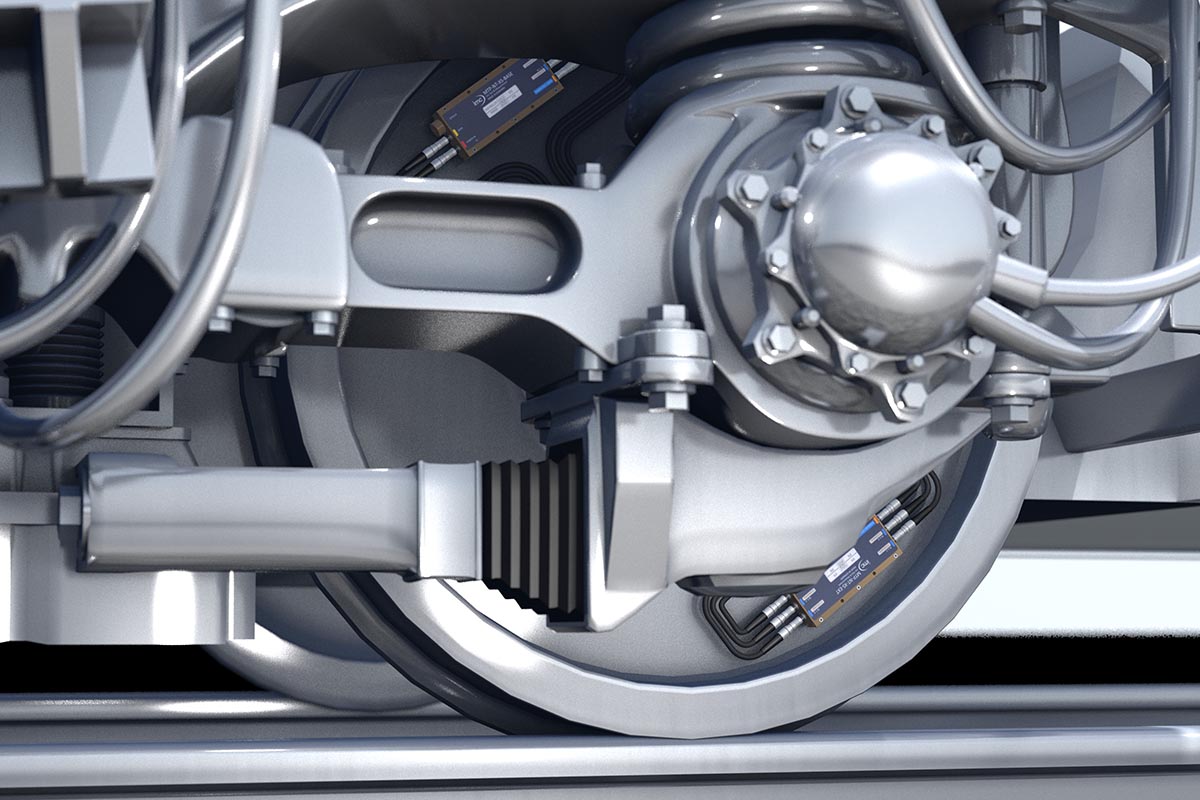

A proven method for direct measurement combines strain gauge technology, wireless telemetry, and a data acquisition system.

Measurement: Strain Gauges (SG)

Forces acting on the wheel cause micro-deformations in the wheel and axle shaft. Strain gauges detect these tiny deformations and convert them into electrical signals. To measure wheel forces, SGs are applied to the original wheel discs in defined patterns, capturing strain in the relevant zones. With the help of a calibration matrix, these signals are translated into precise values such as:

- Vertical wheel loads

- Lateral forces

- Moments

Key advantages of SG-based measurement include high accuracy and robustness under heavy loads, vibration, dirt, and temperature fluctuations. Multi-channel SG configurations allow precise reconstruction of wheel–rail contact forces.

Transmission: Wireless Telemetry

Transmitting the strain gauge signals from the rotating wheel to the onboard data acquisition unit requires a reliable wireless system.

The imc MTP-NT telemetry system digitizes the SG signals close to the sensor with high accuracy and bandwidth, and transmits them from the rotating wheel disc to the receiver without loss.

Typical system components include:

- Rotor unit: mounted on the axle, powering the SGs and acquiring the measurement signals

- Stator unit: wirelessly receives and forwards the data

- Power supply: contactless via induction or battery-supported

Key features of modern telemetry systems:

- Bandwidth up to 24 kHz

- Signal digitization near the sensor for noise immunity

- High transmission stability, even under EMC exposure

- Low latency – ideal for real-time analysis

- Suitable for both test benches and onboard applications

Data Acquisition & Real-Time Processing

For precise and reliable data handling, the imc CRONOSflex modular DAQ system is used. It synchronously acquires all telemetry data and computes forces and moments in real time during measurement. This makes directly interpretable variables such as vertical wheel loads, lateral forces, and resulting stresses available immediately – without any offline post-processing.

In addition, the system platform provides real-time functions such as online classification (e.g., compliance with EN 14363 or UIC standards) and online frequency analysis (FFT), allowing vibration and dynamic effects to be evaluated directly during the test run. Engineers thus gain immediate, actionable insights into the vehicle’s operational behavior.

The modular system architecture also enables easy expansion with additional sensors such as accelerometers, temperature probes, or displacement sensors – ensuring a comprehensive view of the wheel–rail interaction.

More about the imc CRONOSflex DAQ system:

https://www.imc-tm.com/products/daq-hardware/imc-cronosflex/overview

Your Benefits with an imc Solution

✅ Precise force data at the wheel–rail interface

✅ Contactless, low-maintenance signal transmission

✅ Real-time results thanks to onboard calculations of forces and loads

✅ Expandable with acceleration, temperature, speed, displacement, and more

✅ Flexible use in both field tests and lab test benches

✅ Online classification and frequency analysis

✅ High accuracy and long-term stability

Conclusion

Wheel force measurement with strain gauges and telemetry delivers precise, reliable data under real operating conditions – indispensable for vehicle development, certification, and fleet monitoring. It provides a solid data basis for engineering and operational decisions, enhances safety, reduces wear, and shortens testing cycles – delivering measurable progress on the rails.

Questions? We’re Here to Help!

Planning a wheel force measurement or looking to optimize an existing setup? Our experts support you in selection, integration, and evaluation – tailored precisely to your vehicle and application.